Closed loop flash evaporation dryer is a new type of closed dryer developed by Jiangsu Yutong based on advanced foreign technology. The closed-circuit drying system works in a closed environment, and the drying medium is inert gas, which improves the safety factor of the equipment. It realizes the drying production and recovery of organic solvents and solvent materials in the fields of pharmaceuticals, biochemistry, chemical engineering, biology and other technologies, and has the practicality of safe production, high efficiency, low consumption, energy saving and emission reduction.

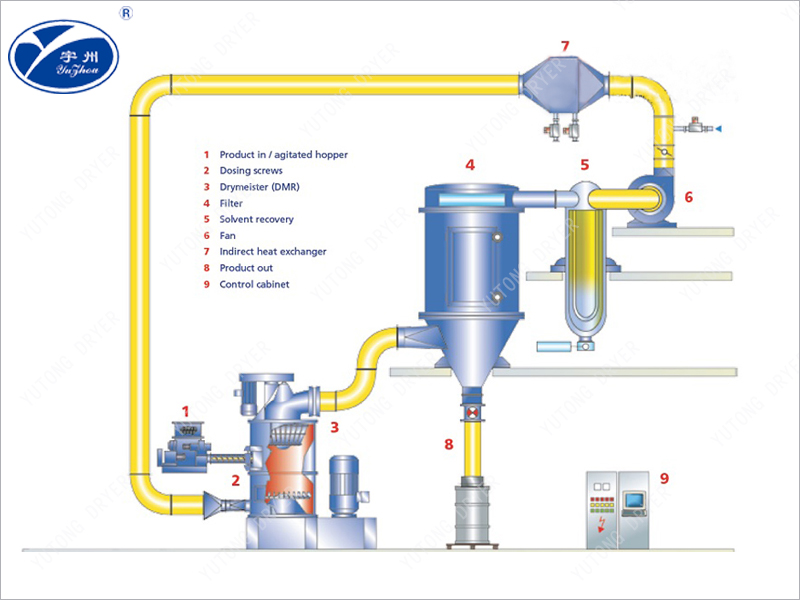

The closed-loop flash dryer consists of a drying machine, heater, bag filter, condenser, fan, and material bin. The entire drying process is carried out under extremely low oxygen conditions under nitrogen protection, resulting in good product quality and avoiding the risks of oxidation, decomposition, combustion, and explosion. This system can solve the problems of organic solvent recovery, drying of easily oxidizable and toxic materials, and is suitable for drying and recovering flammable, explosive and toxic filter cake like, paste like, slurry like materials, as well as organic solvent containing materials.

Before using the system, use nitrogen to replace the air inside the system, so that the oxygen content in the system reaches the safe concentration of the solvent. After being heated by the heating equipment, the circulating nitrogen enters the flash dryer. The wet material enters the spiral feeding mechanism of the flash dryer through the conveying device, and the spiral feeder can be variable frequency controlled. The material is transported by a spiral conveyor into the drying and crushing chamber, and then crushed by high-speed rotating blades with different angles. It is then impacted by the high-temperature airflow entering the cyclone drying chamber and rotates at high speed, causing it to rise and fall rapidly. At this point, the temperature of the airflow drops rapidly, and the moisture in the material evaporates rapidly, completing the drying process. The oversized material is blocked by the elution ring and falls into the drying and crushing chamber to continue crushing until fine powder is obtained.

The dried material enters the cyclone separator with high-speed and high-temperature airflow. At this time, more than 95% of the material is separated and sinks into the collection bin, while the remaining small amount of material enters the pulse bag filter with the airflow. The airflow enters from the outside of the filter bag and is filtered before being discharged upwards. To prevent material accumulation in the filter bag, a pulse solenoid valve is timed to alternately input compressed air from the upper part of each filter bag to blow back the filter bag. The material yield can reach over 99.5%.

The exhaust enters the multi-stage condenser (finned condenser has low pressure drop and good condensation effect), which condenses the solvent in the humid and hot gas. The condensed solvent is collected in a collection tank and stored (zero emission to air, recyclable). After condensation and dehumidification, the dry nitrogen gas is then sent to the heater for circulation through a blower.

(1) This technology uses a rotary mill flash dryer, which refines the material due to centrifugation, shearing, and collision, resulting in a highly dispersed state. The relative velocity between the gas-solid phase is relatively high, which enhances mass and heat transfer; The hot air generates strong rotational motion in the drying room, which has a strong scouring effect on the materials on the wall, eliminating the phenomenon of wall sticking.

(2) The short drying time of the material ensures its quality.

(3) This system is a fully enclosed structure, and the equipment is filled with inert gas (such as nitrogen) inside. When drying anaerobic materials or materials containing flammable and explosive solvents, there is no oxygen in the gas, making it impossible to burn or oxidize. This can effectively prevent equipment from catching fire or exploding during production, making it safer than ordinary equipment.

(4) This system seals all moving equipment with nitrogen and uses an oxygen analyzer to analyze the oxygen content online, improving the safety of the system.

(5) After drying in a closed-loop system, the product is easily cooled within the original system without absorbing moisture.

(6) Due to closed-loop operation, no exhaust gas or dust is discharged into the atmosphere, so it will not cause environmental pollution.

In the closed-loop flash drying process, the drying medium is generally an inert gas, such as nitrogen or carbon dioxide gas. The heated high-temperature inert gas enters the dryer and undergoes heat and mass exchange with the wet material. The wet material is dried and separated by a cyclone separator and a bag filter; Inert gases with high humidity and low temperature enter the spray tower for cooling and dehumidification, while inert gases with lower humidity content are sent to the heater for heating by a circulating fan, and continue to circulate in this way.

(1) Wet material addition

At the feeding port that is prone to leakage, it should be designed with a slight positive pressure to prevent oxygen from the atmosphere from entering. If a star shaped feeder is used, wet materials often block the feeder and prevent it from running. If a general spiral feeder is used for feeding, the spraying phenomenon at the feeding port is severe, the environment is poor, and manual operation is impossible, resulting in abnormal feeding. Therefore, a double helix feeder with staggered blades and interlocking is adopted, and a vertical screw feeding device is installed on the silo to form a material seal, eliminating the spraying phenomenon and ensuring uniform, quantitative, continuous and stable feeding.

(2) Dry product capture

For such light and fine materials, gas-solid separation is difficult. In this closed-loop drying system, if the gas-solid separation is not good, material loss will increase, and it will have a significant negative impact on the subsequent cooling, dehumidification, and heating systems.

(3) Circulating fan

The total resistance of the closed-loop drying system is relatively high. In order to reduce the leakage inside and outside the system, both positive and negative pressure in the system should not be high. This system is designed with two fans connected in series and placed separately, one placed between the bag filter and spray tower, and the other placed between the filter and heater. The shaft seal of the circulating fan has a significant impact on the oxygen content of the drying medium, and the success or failure of the shaft seal design determines whether the entire system can operate normally. After research and analysis, it has been found that in situations where the temperature is high, there is a certain amount of dust, and the lubrication conditions are poor, using magnetic fluid seals can achieve better sealing effects.

(4) Drying medium dehumidification

The drying medium must be dehumidified and reach a lower moisture content before it can be recycled. Generally, the cooling method is used for dehumidification, which can be achieved by using cryogenic liquid or cooling water. The investment and operating costs for cryogenic liquid cooling are both high. The spray tower adopts Bao'er porcelain ring packing, which ensures sufficient and uniform gas-liquid contact and good effect.

(5) Sealing of mechanical rotating parts

There are many mechanical rotating parts in the drying system, such as dampers, feeders, winches, etc. Although their rotational speed is not high, there are many sealing points. If the sealing design is not good, the leakage of the system will be significant. Through experiments, the use of fillers and gas seals has shown better sealing effects.

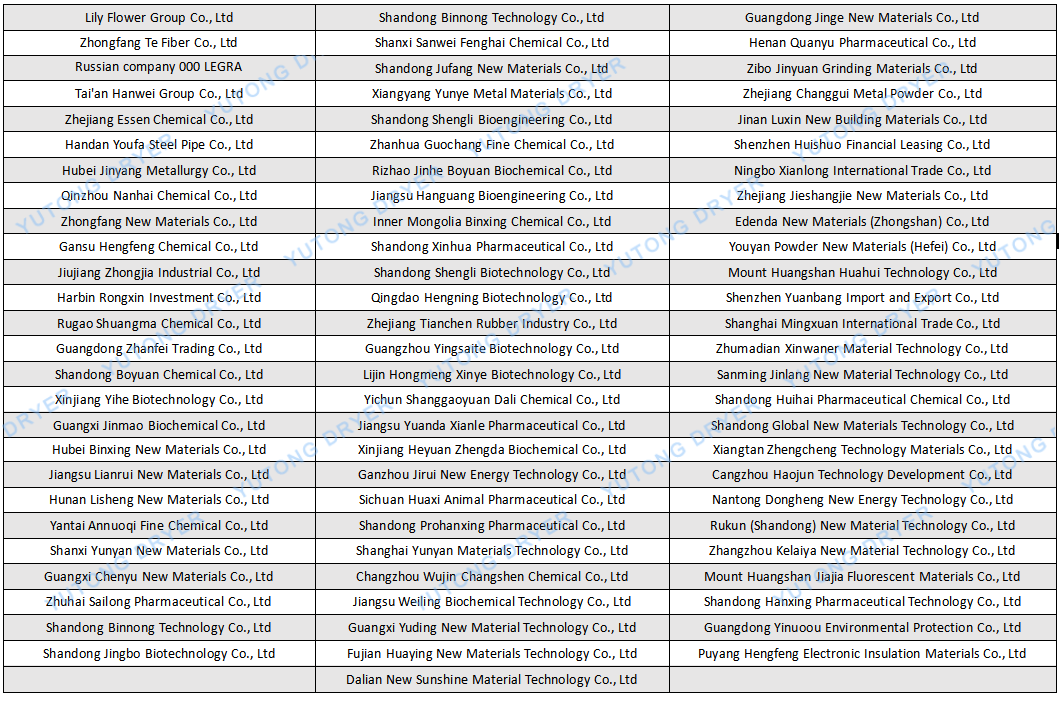

Flash evaporation dryer user list

Previous :QG, FG, GFF series airflow dryers

Next:none!