High speed centrifugal spray dryer is widely used in liquid forming process and drying industry. It is suitable for the production of powder and granular solid products from suspended emulsions, solutions, emulsions and paste liquid raw materials. Therefore, when the particle size distribution, residual moisture content, bulk density and particle shape of the finished product meet accurate standards, the spray dryer is a good drying process.

1. Contact between hot gas and fog droplets: When there is a sufficient amount of hot gas into the spray drying chamber, the direction and Angle of hot gas flow must be considered, whether it is parallel flow, countercurrent or mixed flow, to ensure full contact with fog droplets, in order to carry out adequate heat exchange.

2. atomization: The atomization system of the spray dryer must ensure that the size of the droplets is evenly distributed, which is crucial. Because this can ensure the product quality of the pass rate.

3. pipe Angle and cone Angle design: we have obtained some experience data from the production of nearly a thousand spray drying units, which can be shared with you.

1. the spray drying speed is fast, the material liquid after atomization, the surface area is greatly increased, in the process of contact with the hot air, 95% to 98% of the water can be evaporated instantly, the drying time is only a few seconds, especially suitable for the drying of heat-sensitive materials.

2. the product has good uniformity, fluidity and solubility, the higher the purity of the product, the better quality.

3. The production process of spray dryer is simplified and the operation and control are convenient. For the wet content of 40-60% (special materials can reach 90%) of the liquid can be dried into powder products, dry without grinding and screening, reduce the production process, improve the purity of the product. The particle size, bulk density and moisture of the product can be adjusted by changing the operating conditions within a certain range, and the control and management are very convenient.

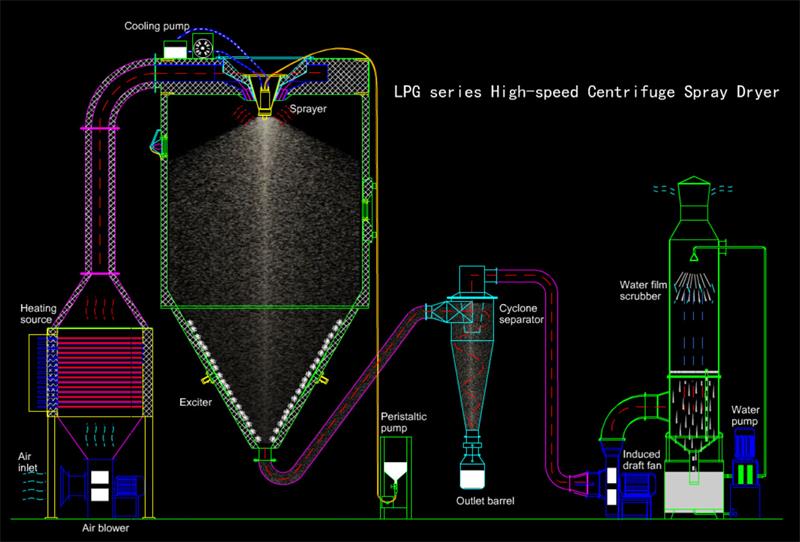

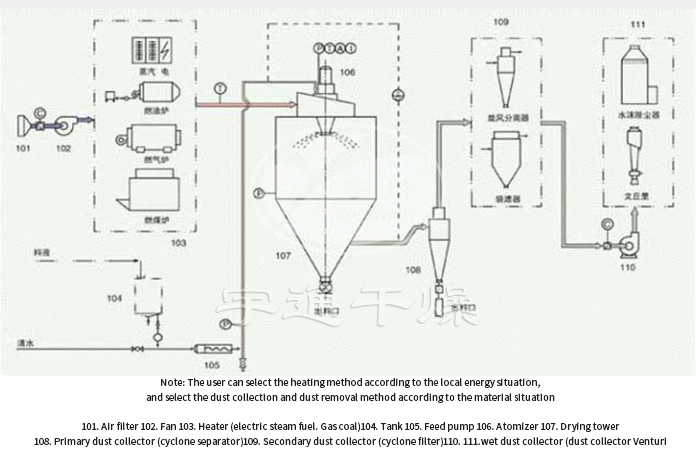

Spray dryer for open circulation, and flow, centrifugal atomization. The drying medium air is filtered by the primary and medium efficiency air filter according to the operation instructions, absorbed by the blower and then heated by the heater through the hot air distributor of the high efficiency filter into the spray drying main tower. The liquid material passes through the peristaltic pump according to the operation instructions, enters the high-speed rotating centrifugal nozzle, and is dispersed into small droplets under the action of centrifugal force. In the main spray drying tower, the small droplets are in full contact with the hot air, and are dried into products after heat exchange along its specific path, and then separated by a cyclone separator, the solid material is collected, and the gas medium is filtered and discharged. The whole spray system is easy to clean, no dead corners, in accordance with GMP requirements.

Chemical products: polyaluminum chloride, disperse dyes, reactive dyes, organic catalysts, white carbon black, laundry powder, zinc sulfate, silicon dioxide, sodium metasilicate, potassium fluoride, calcium carbonate, potassium sulfate, inorganic catalysts, all kinds of waste liquid, etc.

Food: Amino acids, vitamins, egg powder, bone meal, seasoning, protein, milk powder, pig blood powder, soy sauce powder, coffee, tea, Portuguese Sugar, potassium sorbate, pectin, flavor, vegetable juice, yeast, starch, etc.

Ceramics: alumina, zirconia, magnesium oxide, titanium oxide, magnesium titanium, clay, China clay, all kinds of ferrites and metal oxides.

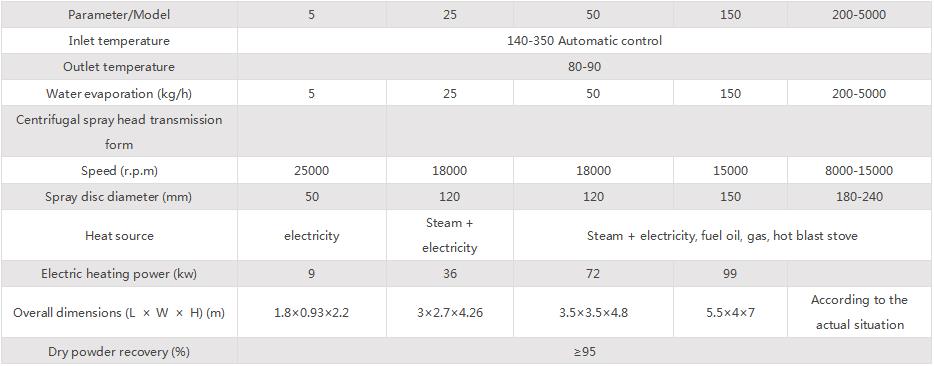

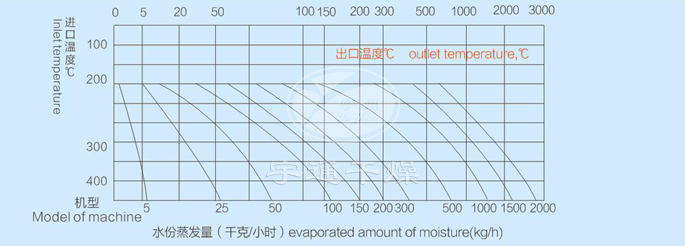

Note: The evaporation rate of water is related to the characteristics of the material and the temperature of the hot air inlet and outlet. When the outlet temperature is 90oC, the water evaporation curve is shown in the above figure (for selection reference). As the product is continuously updated, relevant parameters may change without prior notice.

1, the name of the material liquid, physical properties: solid content (or water content), viscosity, surface tension, PH value.

2, after drying powder capacity, permissible residual water content, particle size, permissible maximum temperature.

3, output, daily opening time.

4, available energy: steam pressure available, electricity capacity, for coal, oil, gas.

5, control requirements: whether the inlet and outlet temperature need to be controlled.

6, powder collection requirements: whether to install bag trap, environmental requirements for exhaust emissions.

7. Other special requirements.

Previous :QPG series airflow spray dryer